| Type | SJ50×2-900 | SJ55×2-1200 |

| Max. film layflat(mm) | 800 | 1100 |

| Film thickness/layer(mm) | 0.02-0.15 | 0.02-0.15 |

| Suitable raw material | HDPE/LDPE/LLDPE/EVA | HDPE/LDPE/LLDPE/EVA |

| Max. output(kg/h) | 100 | 120 |

| Screw diameter(mm) | ☑50×2 | ☑55×2 |

| Screw L/D ratio | 30-1 | 30-1 |

| Max. rotation speed of screw(r/min) | 90 | 90 |

| Power of extrusion motor(kW) | 15×2 | 18.5×2 |

| Mold diameter(mm) | LDPE 200 | LDPE280 |

| Total power(kW) | 45 | 55 |

| Towing speed(m/min) | 90 | 90 |

| Total weight(T) | 3.5 | 4.5 |

| Dimension(L×W×H)(m) | 6.4×2.6×5 | 6.5×3×6 |

Frequently Asked Questions

-

What defines a high-quality "Bag Making Machine" for industrial use?

A high-quality bag making machine, such as the PEASHIN SJ50×2-900 & SJ55×2-1200 ABA Film Blowing Machine Series (with Automatic Roll Changing Winder), must balance precision cutting with high-strength sewing. For industrial liners, the ability to automate the inserting and gusseting process is what separates professional-grade equipment from standard cutters.

-

Can the SJ50×2-900 & SJ55×2-1200 ABA Film Blowing Machine Series (with Automatic Roll Changing Winder) be customized to meet specific production requirements?

Absolutely. As a direct manufacturer, PEASHIN offers extensive customization options for the SJ50×2-900 & SJ55×2-1200 ABA Film Blowing Machine Series (with Automatic Roll Changing Winder). We can modify the machine's width, integrate it with your existing bag-making lines, or add specific sensors and modules to handle unique material thicknesses. Contact our technical team for a tailored solution that fits your exact workflow. -

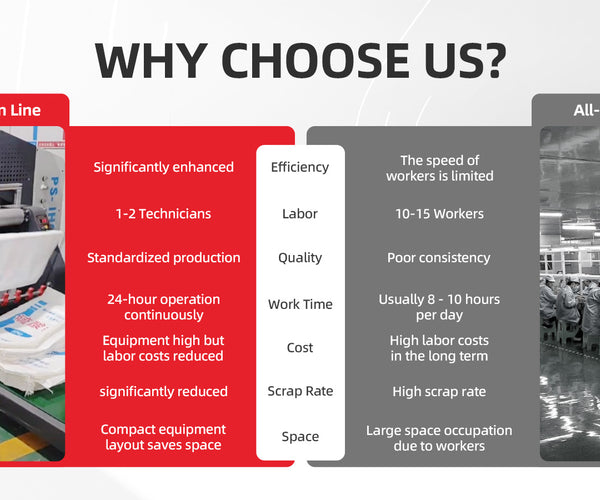

How does the SJ50×2-900 & SJ55×2-1200 ABA Film Blowing Machine Series (with Automatic Roll Changing Winder) improve production efficiency compared to manual or semi-automatic methods?

By integrating high-speed cutting and automatic hemming into a single workflow, the SJ50×2-900 & SJ55×2-1200 ABA Film Blowing Machine Series (with Automatic Roll Changing Winder) significantly reduces material waste by up to 8% and eliminates manual errors. Its automated PLC-controlled system ensures consistent fold quality at high speeds, allowing factories to increase output while lowering labor costs and improving the overall ROI of the production line. -

Does PEASHIN provide international installation and after-sales support for the SJ50×2-900 & SJ55×2-1200 ABA Film Blowing Machine Series (with Automatic Roll Changing Winder)?

Answer: Yes, we provide comprehensive global support. For every SJ50×2-900 & SJ55×2-1200 ABA Film Blowing Machine Series (with Automatic Roll Changing Winder) unit, PEASHIN offers detailed video installation tutorials, 24/7 remote technical assistance, and a 1-year warranty on core components. If required, we can also dispatch experienced engineers for on-site commissioning and professional staff training at your facility.

-

What quality certifications and safety standards does the SJ50×2-900 & SJ55×2-1200 ABA Film Blowing Machine Series (with Automatic Roll Changing Winder) comply with?

Every SJ50×2-900 & SJ55×2-1200 ABA Film Blowing Machine Series (with Automatic Roll Changing Winder) is manufactured in our ISO9001-certified facility and fully complies with CE international safety standards. We use high-quality electrical components (such as Delta or Schneider) to ensure long-term stability and operational safety, making it a reliable choice for heavy-duty industrial environments.