- Edge sewing bag.paper-plastic sewing bag can be applied to this machine

- Self-bagging.self-correcting

- Inner lining bag automatically ironing bottom

- Automatic bottom feeding

- Hot melt adhesive edge,servo automatic trimming.automatic bag counting

- The whole machine adopts PLC micro-computer system control,user-friendly large screen LED interface (10 inches)data display/record/set

- Easy to operate

The unit can be used as hot melt adhesive for back sealing

| Width of outer pocket | 350-600mm |

| Length of outer bag | 600-1200mm |

| Stitch range | 70-12mm |

| Production speed | 16-24pcs/min |

| Total power | 24.6KW |

| Outside size | 13500x2000x1800mm |

Frequently Asked Questions

-

What defines a high-quality "Bag Making Machine" for industrial use?

A high-quality bag making machine, such as the PEASHIN Full Automatic Inner Seam Bag Stamping Bottom, Hot Melt Adhesive Edge Wrapping Machine, must balance precision cutting with high-strength sewing. For industrial liners, the ability to automate the inserting and gusseting process is what separates professional-grade equipment from standard cutters.

-

Can the Full Automatic Inner Seam Bag Stamping Bottom, Hot Melt Adhesive Edge Wrapping Machine be customized to meet specific production requirements?

Absolutely. As a direct manufacturer, PEASHIN offers extensive customization options for the Full Automatic Inner Seam Bag Stamping Bottom, Hot Melt Adhesive Edge Wrapping Machine. We can modify the machine's width, integrate it with your existing bag-making lines, or add specific sensors and modules to handle unique material thicknesses. Contact our technical team for a tailored solution that fits your exact workflow. -

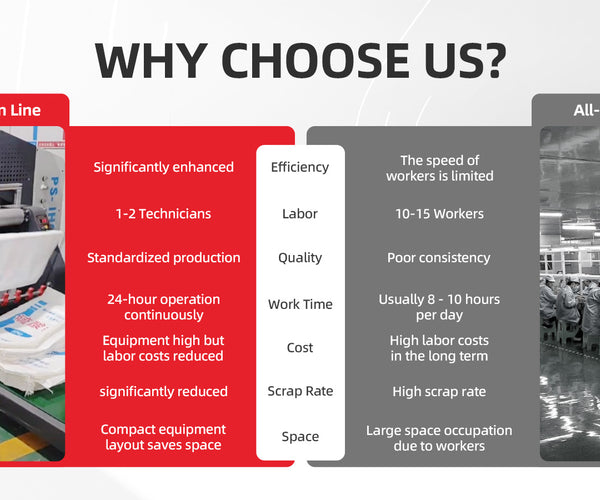

How does the Full Automatic Inner Seam Bag Stamping Bottom, Hot Melt Adhesive Edge Wrapping Machine improve production efficiency compared to manual or semi-automatic methods?

By integrating high-speed cutting and automatic hemming into a single workflow, the Full Automatic Inner Seam Bag Stamping Bottom, Hot Melt Adhesive Edge Wrapping Machine significantly reduces material waste by up to 8% and eliminates manual errors. Its automated PLC-controlled system ensures consistent fold quality at high speeds, allowing factories to increase output while lowering labor costs and improving the overall ROI of the production line. -

Does PEASHIN provide international installation and after-sales support for the Full Automatic Inner Seam Bag Stamping Bottom, Hot Melt Adhesive Edge Wrapping Machine?

Answer: Yes, we provide comprehensive global support. For every Full Automatic Inner Seam Bag Stamping Bottom, Hot Melt Adhesive Edge Wrapping Machine unit, PEASHIN offers detailed video installation tutorials, 24/7 remote technical assistance, and a 1-year warranty on core components. If required, we can also dispatch experienced engineers for on-site commissioning and professional staff training at your facility.

-

What quality certifications and safety standards does the Full Automatic Inner Seam Bag Stamping Bottom, Hot Melt Adhesive Edge Wrapping Machine comply with?

Every Full Automatic Inner Seam Bag Stamping Bottom, Hot Melt Adhesive Edge Wrapping Machine is manufactured in our ISO9001-certified facility and fully complies with CE international safety standards. We use high-quality electrical components (such as Delta or Schneider) to ensure long-term stability and operational safety, making it a reliable choice for heavy-duty industrial environments.